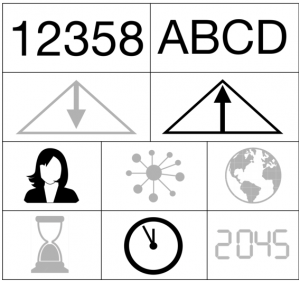

Life Cycle Analysis

Quantitative - Qualitative

Deductive - Inductive

Individual - System - Global

Past - Present - Future

In short: A Life Cycle Analysis attempts to analyze the (socio-)environmental impact of a product through its lifespan.

Contents

Background

Life Cycle Analysis, or Life Cycle Assessment (LCA), dates back to the late 1960s/early 1970s when the first (partial) LCAs were conducted: "The scope of these studies was initially limited to energy analyses but was later broadened to encompass resource requirements, emission loadings and generated waste. LCA studies in this period mainly focused on packaging alternatives." (Guinée 2011, p.9; 5) Here, a study done for the Coca-Cola company set the foundation for subsequent life cycle analyses (4). Yet, the method was not unified at all, but existed as a broad variety of theoretical frameworks and methodological approaches. This led to a lack of comparability between the results and hindered the method from becoming an accepted analytical tool until the 1980s (1).

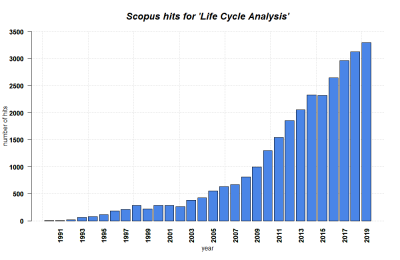

During the 1980s, the Green Movement in Europe strengthened public interest in the method (4). In the 1990s, its image and usefulness improved through the engagement of SETAC (Society of Environmental Toxicology and Chemistry) and ISO (International Organization for Standardization) in the harmonization and standardization of LCAs. At this time, the method also first appeared in scientific publications (1).

Since the year 2000, LCAs have been increasingly adopted by policy actors (such as the EU, US and UN). Alongside a publicly increasing role of life-cycle-thinking, more diverse forms of the LCA have been been developed that differ in terms of their system boundaries, allocation methods and the considered impacts (1).

More recently, the Life Cycle Sustainability Assessment (LCSA) has been suggested to better connect LCAs with the sustainability discourse. The LCSA broadens the scope of the LCA both in terms of criteria involved (from purely environmental to economic, environmental and social impacts) and regional scope (from the product to the industry) while deepening the perspective on the elements involved in the Life Cycle (1, 2, 3). While this approach is still in development, it may be seen as one/the future of the Life Cycle approach (see Outlook).

What the method does

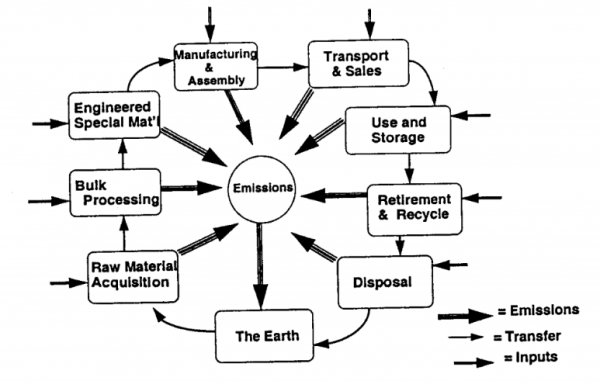

The underlying idea of the Life Cycle Analysis is that the environmental impact of a product. activity or process is not to be found in the use, but (mostly) its production, transportation and disposal. The LCA thus attempts to gather a quantitative overview on the resources used and the waste / emissions produced during the whole 'life' of any given product - 'from cradle to grave' - to provide a more accurate account of its environmental footprint (1, 4, 5). Based on this, comparisons between similar products may be made or a company (or policy-maker) is enabled to decide which processes or materials might reasonably minimize the environmental impact of a product in order to subsequently act on these insights (4, 5). A LCA is also often conducted internally for a company to learn about potential energy - and thus cost - savings and in order to substantiate marketing claims about the environmental compatibility of a product (4).

A LCA consists of four steps (4, 5).

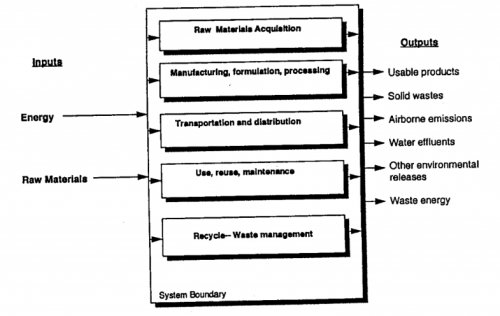

- First, the scope of the analysis is defined. This includes the elements (processes, inputs and outputs) that are to be considered and the boundaries of the analysis (see Fig. 3). The boundaries are crucial, since they do not only define what is to be studied, but also which elements are left out of the analysis - e.g. socio-economic impacts of the product (4). Each LCA may define the system's boundaries and individual steps differently, which is why the proper documentation of the specific system definition is relevant to allow for comparability with other studies (4). The same is true for the in- and outputs which need to be defined according to specific standards (5; see Further Information for ISO standardization). This harmonization and unambiguous definition and documentation further assures a valid interpretation of the data (4).

- Second, the inventory analysis. During this step, quantitative data on the direct and indirect in- and outputs that arise during the life-cycle of the analyzed product are gathered (materials, energy, emissions, waste, see Fig. 3). This step requires caution in many regards in order to aggregate the data correctly (see appropriate use of inventory data in Strengths & Challenges).

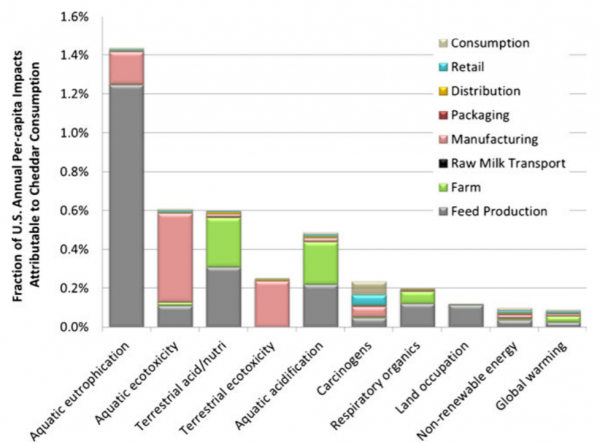

- Third, the impact analysis phase. This step begins with the selection of environmental impact categories, such as climate change or ecotoxicity, each with relevant indicators, like the frequency of natural disasters or the health of aquatic ecosystems. Next, the results from the life cycle inventory are assigned to these impact categories. Finally, the environmental impacts are calculated (7). The latter is done by multiplying the inventory emission of a specific compound (e.g. CO2 per unit of measurement) with a characterisation factor that is provided in the literature or an official database. This multiplication yields the impact of the emission on the chosen category indicator. As an example, the amount of carbon dioxide emitted in the life cycle of a product can be translated (by the use of the characterisation factor) into its level of contribution to climate change, often represented by an increased likelihood of natural disasters due to global warming.

- Lastly, the improvement analysis which highlights the possible changes to be made by policy actors or companies to the life-cycle processes of the product. These actors may use the conclusions of this step to prioritize their potential future decisions.

Strengths & Challenges

- For companies, conducting LCAs to their products may lead to "(...) better and less-polluting products that are less expensive and provide a marketing edge over the competition" (Ciambrone 1997, p.3).

- LCAs can also be a powerful tool for policy-making and the development of new technologies and products, especially with a focus on sustainability. They can also help the customer and the public get a better understanding of the environmental impacts of products (see Normativity).

- Whenever a LCA is conducted with the intent of publishing the data, but based on company-internal data, the question of confidentiality must be addressed (4). Confidential data may be erroneous and can hardly be verified by external readers, which may disguise analytical errors (5).

- The appropriate use of inventory data is of special importance for the LCA, and a variety of pitfalls may arise in the inventory phase.

- The researcher must ensure the up-to-dateness of the data and take into the account the (temporal) specificity of the data as opposed to average numbers. A sufficiently long time period of data is advisable to smooth out individual variations (4).

- The researcher must make sure that the data is normalized for each product (4).

- Some data may not be obtainable, in which case it is interesting to ask why it is not, and how important this data is to the overall LCA results. If an emission is not (easily) measurable, a qualitative discussion of its amount might be reasonable, which should then be properly reflected upon (4).

- When analyzing and synthesizing the data from individual steps of the life cycle, the researcher must be aware of uncertainty of the respective datasets. If the uncertainty of one - or several combined - datasets becomes too high, the overall result might not be valid enough to serve the intended purpose. In this case, a test for sensitivity of the overall result with regards to the exclusion or inclusion of said data is advisable to check the relevance of the data for the general conclusion (4).

- In terms of analysis, the researcher must be aware of potential differing conditions within an industry (deviating regulations and standards, other technologies, materials and processes) if the purpose of the LCA is a product comparison (4).

Quality criteria for the LCA are (4):

- quantitative data that is synthesizable and comparable to the results of other LCAs,

- replicable information with sufficient documentation,

- a scientific approach to the data gathering and analysis,

- a comprehensive assessment of all significant resources and emissions,

- sufficiently detailed data with regards to the study purpose,

- peer-reviewed quality assurance in case of public use and

- usefulness of the results for further integration.

Normativity

- Often, products are hardly comparable due to varying product characteristics whose (dis-)advantages depend on choices that are not in the hands of the producer. Thus, "(...) in many - perhaps most - cases LCA can only expose the trade-offs. It can only rarely point unambiguously at the 'best' technological choice." (Ayres 1995, p.201)

- It should be noted that the results of LCAs can serve not only as information on how to decrease manufacturing costs of a product, but also as marketing material for companies. These two elements of the LCA are market-related side effects of the environmental impact reduction that is - or should be - the main goal of the LCA. Therefore, when reading a company-led publication of LCA results, one should be aware of potential selectivity in the data that is intended to proclaim a specific image of the company or product (4).

- In addition, knowledge about the environmental (and/or social) footprint of any product has potential implications for consumer behaviour. A good example for this is the plastic vs paper bag discussion, which acknowledges the carbon footprint during the production of both products as well as the environmental consequences of their (inappropriate) disposal, indicating a differentiated perspective on the issue (see (4)). Another example is the discussion of electric vs non-electric vehicles, where the energy consumption during the production and the usage of the car are taken into consideration, but also the social costs of battery manufacturing. The assessment of all relevant impacts of the product and thus the (non-)purchase decision is in the hands of the consumer. In this regard, the LCA allows for more informed decisions but can also be misleading if not conducted and communicated properly.

Outlook

As mentioned before, the LCSA approach, including considerations of sustainability into Life Cycle Assessments, may constitute the future direction of the field. As of now, this approach is not fully developed and important challenges persist, but the discourse about acknowledging the wider impacts of products is ongoing and can be expected to further shape the method (for more on the LCSA, see (2) and (3)).

Key publications

- Ciambrone, D.F. 1997. Environmental Life Cycle Analysis. CRC Press.

A detailed description of the LCA process.

References

(1) Guinée, J.B. 2011. Life cycle assessment: past, present and future. International Symposium on Life Cycle Assessment and Construction, Nantes, France.

(2) Zamagni, A. Pesonen, H.-L. Swarr, T. 2013. From LCA to Life Cycle Sustainability Assessment: concept, practice and future directions. International Journal of Life Cycle Assessment 18. 1637-1641.

(3) Guinée, J. Life Cycle Sustainability Assessment: What Is It and What Are Its Challenges? In: Clift, R. Drucklman, A. (eds.) Taking Stock of Industrial Ecology. Springer Cham. 45-68.

(4) Ciambrone, D.F. 1997. Environmental Life Cycle Analysis. CRC Press.

(5) Ayres, R.U. 1995. Life cycle analysis: A critique. Resources, Conservation and Recycling 14. 199-223.

(6) Kim, D. Thomas, G. Nutter, D. Milani, F. Ulrich, R. Norris, G. 2013. Life cycle assessment of cheese and whey production in the USA. International Journal of Life Cycle Assessment 18. 1019-1035.

(7) Pennington, D.W. et al. 2004. Life cycle assessment Part 2: Current impact assessment practice. Environment International 30. 721-739.

Further Information

- Standards for LCAs are maintained by ISO who publish new iterations regularly. The current version of the LCA standard is ISO 14044 which is accessible here.

The author of this entry is Christopher Franz.